Advertisement

Trending in Health

Advertisement

Know how to prevent, treat and control the symptoms of various diseases and medical conditions. We explain what's happening in your body when disease strikes, and what you can do to feel better faster.

Whether you're choosing a doctor or trying to navigate health insurance jargon, these articles will help you understand the health insurance system.

The human body is an amazing structure made up of many fascinating parts and systems. Learn about the human body and how its systems work together.

Love and relationships are a major part of the human experience, but they mystify many of us. Learn what scientific research has to say about love, and get advice on creating and maintaining relationships.

Medicine has to do with diseases and conditions that affect the entire body. In this section, learn about testing and treatment plans including the medicines used to prevent and treat a range of diseases and conditions.

FDA Approves OTC Narcan Nasal Spray for Opioid Overdose

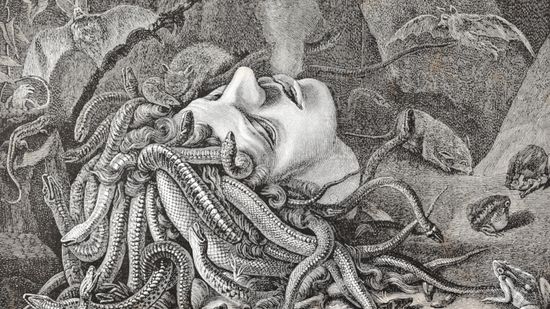

FIND OUT MOREMedical Schools Have Come a Long Way From Grave Robbing to Get Cadavers

FIND OUT MOREMark Cuban Wants to Solve the U.S. Prescription Drug Price Crisis

FIND OUT MOREWhy Are Potassium Iodide Pills Selling Like Crazy?

FIND OUT MOREFind articles on stress, phobias and schizophrenia. This section offers information on a range of mental health issues.

From conception to cradle, the Pregnancy and Parenting Channel guides you on the journey to parenthood. Learn what to expect when you're expecting.

Skin care is a broad term that refers to everything from hygiene to anti-aging regimens. Learn more about skin care at HowStuffWorks.

There are many approaches and countless factors that make up a persons overall wellness. HowStuffWorks has extensive coverage on the different types of natural medicine such as DIY remedies and traditional Chinese medicine.